Your End-to-End Fabrication Partner

A strategic partnership with Miller Fabrication Solutions is designed to strengthen your core competencies, not your risk. Find out how you can increase focus on forging your product innovation.

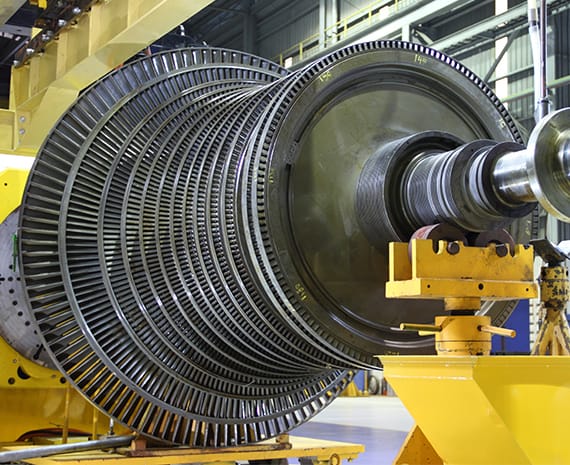

State-of-the-Art Equipment & Facilities

A true strategic partner will have the resources and flexibility to adapt to your ever-changing requirements. For Miller Fabrication Solutions, this means a continual evaluation of existing and new equipment, technologies, processes and standards to ensure your projects are handled efficiently and effectively.

Total Solutions

Value-Added Solutions

Manufacturing Solutions

Lyndie Wingenroth

Independent Rough Terrain Center, LLC (IRTC)

“We have over 250 suppliers. When we look at potential partners, we look at the quality they provide, their costs and delivery time. Miller has delivered on all three.”

Jeffery Snider

Volvo Construction Equipment

“Miller Fabrication Solutions has become our preferred supplier, implementing lean manufacturing principles and numerous quality and delivery improvements that benefit our bottom line. They have made capital investments to support our growth. Miller Fabrication Solutions has not only met our goals but exceeded them, becoming a true partner for the long-term.”

Chuck Tornga

Tirx Moto

“The extensive manufacturing capabilities of Miller were a pretty quick indicator that this company could take on not only significantly complex projects but a variety of production volumes.”

Celebrating 60 Years of innovation

2023 marked 60 years of operations for Miller Fabrication Solutions. Since David R. Miller began his three-person welding and machining operation in 1963, the company has grown to 400 employees across four western Pennsylvania plant locations comprising 675,000 square feet. To this day, Miller continues to invest in new technology and automation, its people and the communities it serves.

Have a Project?

Keep your equipment production lines moving.

Send us your drawings, specs and other documentation to see how we may be able to assist with your metal fabrication project.

Prefer to talk it through? You can also schedule a time with us by clicking the button below and booking directly on our calendar.

BOOK A TIME

Prefer to talk it through? You can also schedule a time with us by clicking the button below and booking directly on our calendar.

Latest Blog Postings

Blog

December 11, 2025

Mike Carrier: A Career Shaped by Curiosity and TechnologyCorporate

September 18, 2025

Dave Hetrick Keeps Machines Running Over a 35-Year Career