Welding

Industrial Welding Services. Done Right. The First Time.

When you’re searching for a heavy fabrication welding expert to supply you with the parts that make your equipment work to its full potential, you know that you need a fabrication partner that you can depend on for high quality, on-time production scheduling and delivery and reliability. Anything less will cost you time and money. From quality components to new innovations to work with your demand schedules, we give you a turnkey solution for all of your OEM welding needs.

Quality and Safety are among our top goals with everything that we do, and we’ve been recognized for taking the steps to go above and beyond when it comes to our welding solutions. In 2019, our team won the Manufacturing Leadership Award for our internal Weld Training program. All of our training sessions are a part of our Zero-Defect Mission.

Manual and Robotic Welding

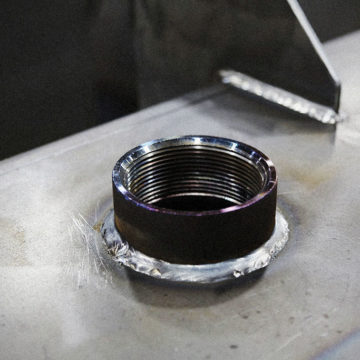

Our three facilities include a wide variety of specific equipment for both manual and robotic welding. Our robotic equipment includes state-of-the-art, CNC-programmed robotic welding machines that can fabricate up to 20 tons. Gas metal arc (GMAW or MIG) welding arms weld multiple joints simultaneously. For manual welding needs, we use nine welding positioners for different weight capacities, allowing us to do manual work on any parts ranging anywhere from 1,000 to 30,000 pounds. Our lengthy equipment list helps to make our low-volume/high-mix production possible. And our ability to customize solutions in an effort to meet the tightest demands has allowed us to form numerous partnerships with OEMs across a variety of industries.

Our careful planning, responsive customer service and value-added solutions demonstrate that we can meet surges of demand to help you take advantage of a growing market. Our infrastructure is designed to support constant change while still meeting the high standards for which we have become known.

Miller Fabrication Solutions has the equipment and expertise to be your welding fabrication solution for heavy, complex parts – and the quality practices to get it right each and every time. Upload your RFQ/RFP today, and let us know what Miller can do for you.