Industrial Fabrication

Industrial Metal Fabrication Solutions for the Global OEM

For your complex parts and assemblies, Miller Fabrication Solutions has the industrial metal fabrication experience that you’re looking for in a heavy fabricator. Our wide range of industrial fabrication-specific equipment allows us to meet the varied demands of modern equipment manufacturers. We’re constantly enhancing and updating our heavy fabrication capabilities, and as exhibited by our addition of state-of-the-art hydraulic leveling equipment. This machinery produces flat stamped, laser-cut and plasma-cut parts, and levels materials .12 inches to 1.375 inches thick and up to 78.7 inches and 20 feet long. Miller’s three facilities also include CNC cutting machines with capacity up to 72,000 pounds and a variety of saws, presses and burning machines.

Our lengthy equipment list means we can take on a variety of processes, material types and other specifications while maintaining quality across the board. Miller Fabrication Solutions creates custom metal parts that are made with everything from carbon, alloy and stainless steels, to HSLAs and red metals like copper, brass and bronze. Miller can fabricate metal that’s up to 2 inches thick and process metal that’s up to 10 inches in plate thickness.

Miller specializes in heavy fab work, to include comprehensive, value-added solutions like Value Analysis/Value Engineering and Capacity Management to help to keep your fabrication costs low and manufacturing process as efficient and effective as possible. We aim to be your Tier 1 fabrication supplier-partner for the reliability, high-quality, and on-time production scheduling and delivery services that we bring to your supply chain network.

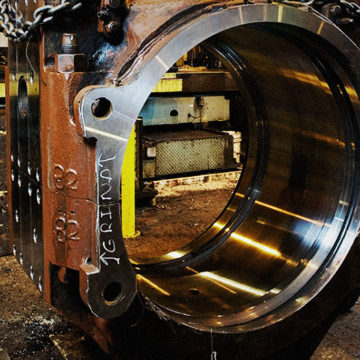

Our solutions work for a variety of OEM industries, and include a customized approach for each of our equipment manufacturing customers, whether we’re fabricating parts for drilling equipment or metal valve and hose parts.

Miller Fabrication Solutions’ combination of years of experience and a forward-thinking attitude puts us a cut above the typical job shop supplier. We’ve been around for over 50 years, yet we’re constantly adapting to the needs of today’s OEM, whether that’s through Internet of Things (IoT) integration or by incorporating new lean manufacturing initiatives to reduce risk and streamline processes. It’s what makes us one of America’s top OEM industrial metal fabricators.

Let us know what we can do for you to make your next project a success!