How Your Supplier Partners Can Help Drive Innovation

April 10, 2018

While tax reform was good news for CEOs, it turns out the that pressure never lets up for supply chain managers. That’s right, you still need to look for ways to improve on-time delivery, inventory management, and reduce costs.

However, this does not need to be a thankless task. In fact, supply chain innovation is increasingly being approached as a collaboration between OEMs and their partners. With that in mind, here is an overview of how your supplier partners can help drive innovation.

Reinventing the Wheel

A simple fact of corporate life is that resources are always constrained. It doesn’t matter if you are working for a multinational organization with multiple divisions in countries around the world or a regional company with a world-class reputation – there never seems to be enough of anything to go around.

While resource scarcity can be frustrating, it has also proven to be fruitful ground for innovation. Think about it, many of the process improvement tools we use today had their genesis on the factory floor – this includes much of the Body of Knowledge we know as ‘lean manufacturing.’

In fact, a central tenet of lean is the concept of incorporating your supplier partners in continuous improvement. This is especially true when it comes to the strategic suppliers of your core components, such as metal fabricators. After all, these are the people you rely on to build great products with outstanding quality and consistency, and all at a competitive price.

As such, this is one time that you want to ‘reinvent the wheel’ by involving partners in the process of innovation. This doesn’t mean you cede responsibility to your partners; rather you want to involve your partners in ways to make your products and processes better.

To Innovate, Start with R&D

While a lot has been written on OEM process improvement, one undeniable fact is that it is very hard to make a flawed product work in production. This highlights the need to tie your manufacturing partners into the R&D process.

Not only will your OEM supplier partners bring intangibles, such as how to make your next great product even better, they will also be able to share the best practices they have gleaned from years of experience making similar products.

This is important as the current structure of the manufacturing ecosystem in the U.S., if not globally, heavily relies on external partners. However, there is often the tendency to favor the lowest cost supplier, who has little or no reason to share their ‘know how’ with their OEM customers. While this approach does result in short-term gains (i.e. lowest price) the benefits tend to diminish over the long-term as the suppliers are less likely to make the investments needed to support new projects. In addition, the overall cost of managing such a supplier can negate cost savings promised by the low price alone.

Does this sound familiar? Unfortunately, it is a dynamic which remains all too common among supply chains, and it usually starts by giving suppliers a supposedly ‘finished’ prototype, which they need to reverse engineer and then ramp up for production.

It doesn’t take a rocket scientist to figure out what could go wrong. But there is a better way – involve your supply chain partners in the R&D process. In fact, when done right, this approach can result in tremendous improvement to your SCOR KPIs.

At a tactical level, assigning a design role to your supplier partners needs to align with the capabilities of their business. This requires a free-flow of communication to unlock the insights needed to deliver a project on time and under budget. By extension, this leads to Six Sigma Cpk and Ppk improvements, which will make the job of managing a complex supply chain easier for everyone involved.

As such, the role of the supply chain manager in this scenario shifts from overseeing production to one of enabling engagement, thus opening the door for innovation.

Still not convinced? According to McKinsey, organizations which collaborate with suppliers experience 2x the EBIT (Earnings Before Interest and Taxes) than their competitors. If this doesn’t get the attention of the folks in the C-Suite, then nothing will.

Still not convinced? According to McKinsey, organizations which collaborate with suppliers experience 2x the EBIT (Earnings Before Interest and Taxes) than their competitors. If this doesn’t get the attention of the folks in the C-Suite, then nothing will.

How to Involve Your Supply Chain Partners

Barriers to innovation exist, especially in heavily-regulated industries. But when it comes to finding a metal fabrication partner to help drive innovation, there are a few questions you need to ask:

- Is the partner’s senior management supportive of the project?

- Do the partner’s capabilities match the project requirements?

- Have you identified the right people to make the integration process work?

- What is the growth plan?

Regarding the last question, this is often overlooked. But sometimes a project is so successful it outgrows your partner’s ability to keep up. As such, having a plan in place to identify growth-related challenges will help to avert a Tesla-type supply chain meltdown.

Partnering with supplier partners to drive innovation is not something which can happen overnight. It is an iterative process, one which requires well-defined roles and responsibilities and people who can drive innovation without impacting relationships.

This is why you make the big bucks.

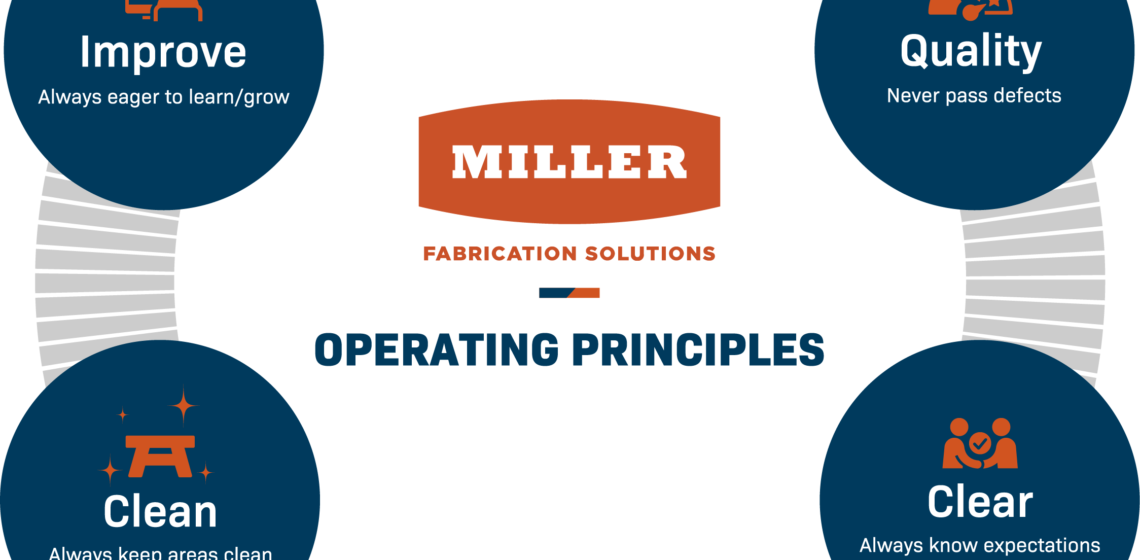

Get to know how JLG Industries, Inc. turned to its fabrication partner, Miller Fabrication Solutions, to help power innovation by improving the overall quality of its components for a heavy sales impact – download the case study today.