Avoiding These 5 Nightmare Supply Chain Scenarios

August 9, 2018

In a perfect world, supply chains are seen but not heard. This doesn’t mean that supply chain professionals should take a backseat in strategic discussions; in fact, they need to be involved every step of the way. However, supply chains rarely get any attention – except when things aren’t running as they should.

We’ve all been there: late deliveries, material shortages, tariffs, and qualities issues gum up the works. The next thing you know, sales and marketing is spooked, and the organization swings into damage control mode.

It doesn’t need to be this way. Sure, challenges will continue to crop up, but that doesn’t mean every day in the office has to feel like going into battle. With that in mind, here are some tips on how to make sure these five nightmare supply chain scenarios don’t happen to you.

Nightmare 1: All Your Eggs in One Basket

It might seem easier to single source a key component, but the reality is that doing so could set you up for some big problems down the line. You may recall the massive flooding in Thailand in 2011 that nearly shut down the global production of PC hard drives.

Supply chains, particularly those within the electronics and automotive industries, are meant to be integrated, modern, and efficient. But the flooding in Thailand illustrated the chaos that can happen when planners put all their “eggs in one basket.”

If this can happen in supposedly ‘integrated’ supply chains, just imagine the potential nightmare scenarios in other industries – maybe even your own. But you don’t need to lose sleep over this, as the answer lies in a combination of planning and monitoring.

There are plenty of times when it may make sense to single source a part or an entire assembly. For example, when working with a strategic metal fabricator who possesses a process or specialty not found among its competitors.

However, you want to work with your partner not only to map out the order fulfillment schedule, but also to develop a backup plan of their own. Doing so will act as a sort of insurance policy in these situations.

The next step is to continually monitor what is going on with your strategic partner. The goal is not to disrupt the partner’s production – rather, it is to respond quickly whenever someone “pulls the cord.” Doing so will allow you to have a conversation with the partner before a hiccup becomes a massive issue.

Nightmare 2: A Laissez-Faire Approach to Supplier Management

Supply chain management is a lot like gardening. While you can’t be there every moment of the day, you do need to be hands on enough to make sure that things are weed-free and growing. Unfortunately, not everyone subscribes to this philosophy. For some supply chain managers, they reckon that supplier-partners make the parts and the rest will take care of itself.

But we live in the real world and this means that you need to facilitate an open conversation with supply chain partners. Quarterly site visits and audits are not enough. Instead, the goal should be an open and frank relationship where challenges can be discussed, and supply chain opportunities can be found.

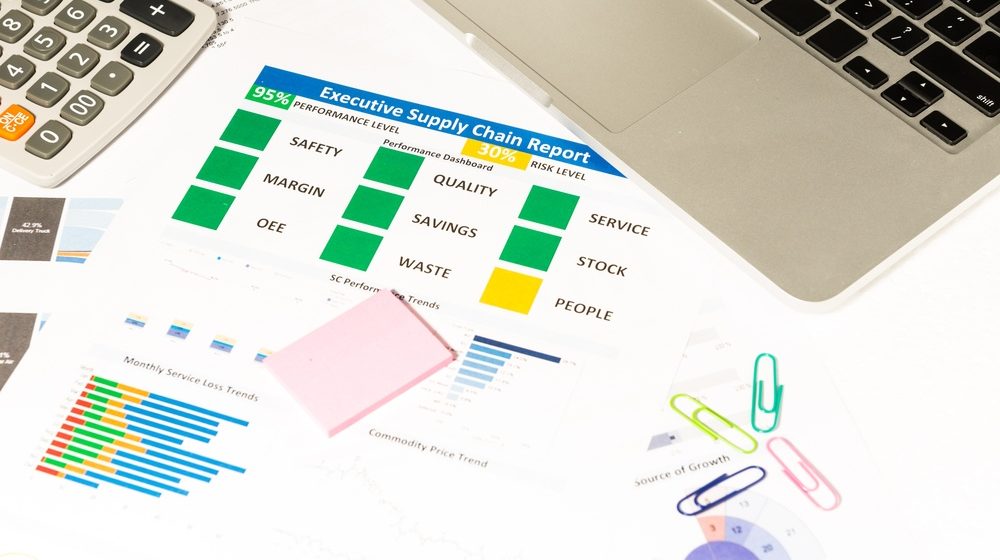

Nightmare 3: Using the Wrong Metrics

Supply chains are all about measurement and most supply chain managers pride themselves on their stats. And why not? Stats, such as full-line time deliveries, on-time deliveries, and quality, help to measure the effectiveness of a supply chain.

However, there are times when the focus can be on the wrong metrics and this can wreak havoc over the long run. The reasons for this are straightforward: collecting the wrong data can lead to a false sense of security, one which can end in disaster.

To address this issue, supply chain managers should periodically review the metrics they are using to see if these data points align with the needs of the customer. Beyond this, data collection processes should also be reviewed to ensure the data being collected is not only accurate, but is gathered in the most efficient manner possible.

Nightmare 4: Garbage In, Garbage Out

As you already know, data collection is important. However, one of the biggest nightmares for a supply chain manager can be trying to reconcile documentation discrepancies. This can happen when bills of lading are manually entered instead of being automated, or even when entry errors cause computerized forms to be incorrect – then add in the fact that most of us tend to take the data provided by computerized systems for granted. This false sense of security can lead to problems – especially when the wrong units or quantity are ordered.

For this reason, data entry systems should include a verification step(s) as it will help to identify any problems before they are passed down the line. While this check should be automated, any system should also include regular audits to ensure data integrity.

Nightmare 5: When Lean Means More Than Cutting the Fat

There is no doubting that lean manufacturing can transform an inefficient operation into a world leader. However, many people (mostly not in supply chain management) equate “lean” with cutting more than just the fat.

This can create problems, as supply chains don’t run by themselves – at least not yet. As such, there are times when you need some level of backup to ensure everything is running smoothly. Maybe backup is needed to cover for when people are not in the office, or to provide the ability to cross-train your team.

Staffing supply chain functions should be tied to the needs of the customer, as this is the ultimate determination of value-add. Such a focus will ensure the organization is staffed to keep customers happy rather than fighting fires all day.

Learn how Miller, a top OEM fabricator, helped a lift and equipment manufacturer during a bind by downloading the case study today.